Our Technology

Our Procedure

Advanced 3D Scanning Technology

Our advanced 3D scanning technology ensures that every detail of the patient’s anatomy is captured with unparalleled accuracy. This level of precision means that the orthotics and prosthetics we produce fit better, function better, and provide greater comfort than those made using traditional methods. We begin with a detailed 3D scan of your foot, capturing every curve, arch, and pressure point. This precise data forms the foundation for our custom insole design, ensuring an unparalleled fit that traditional methods simply can’t match.

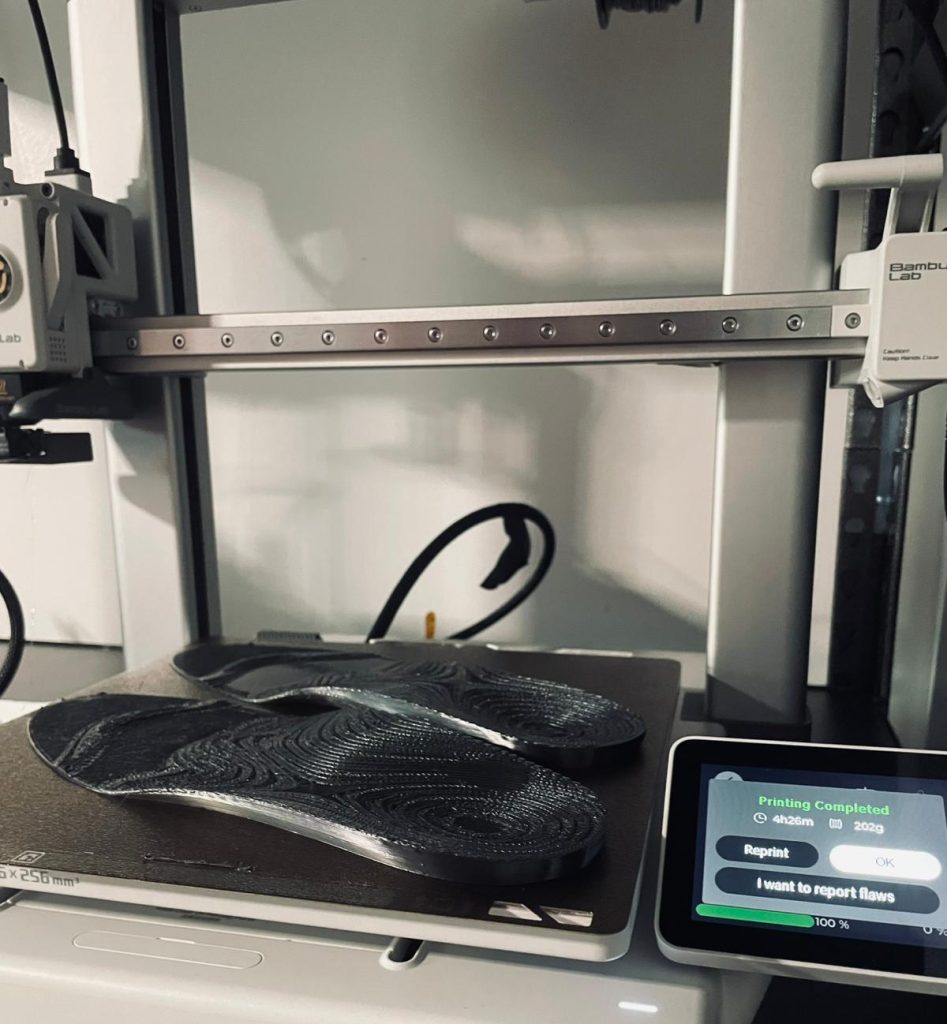

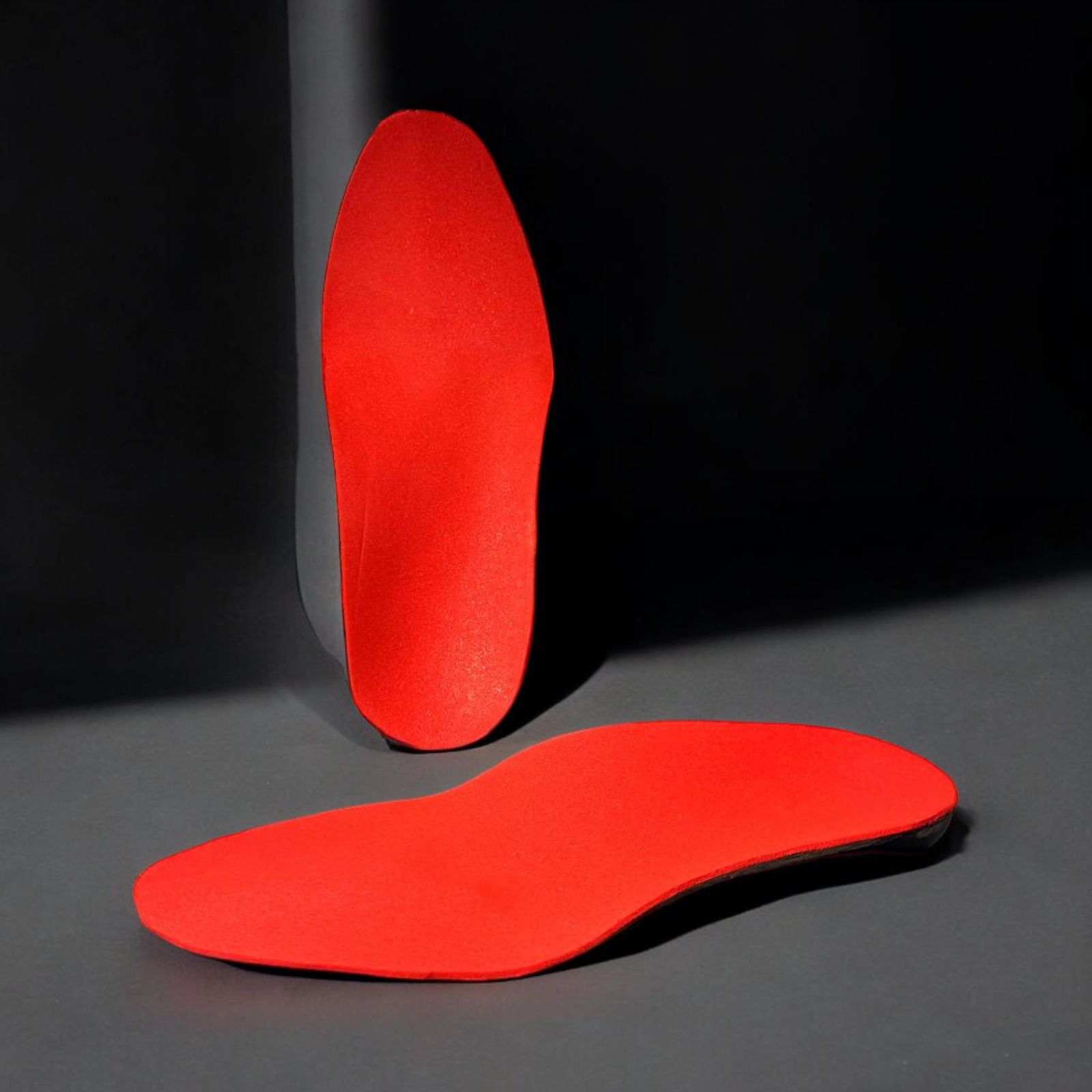

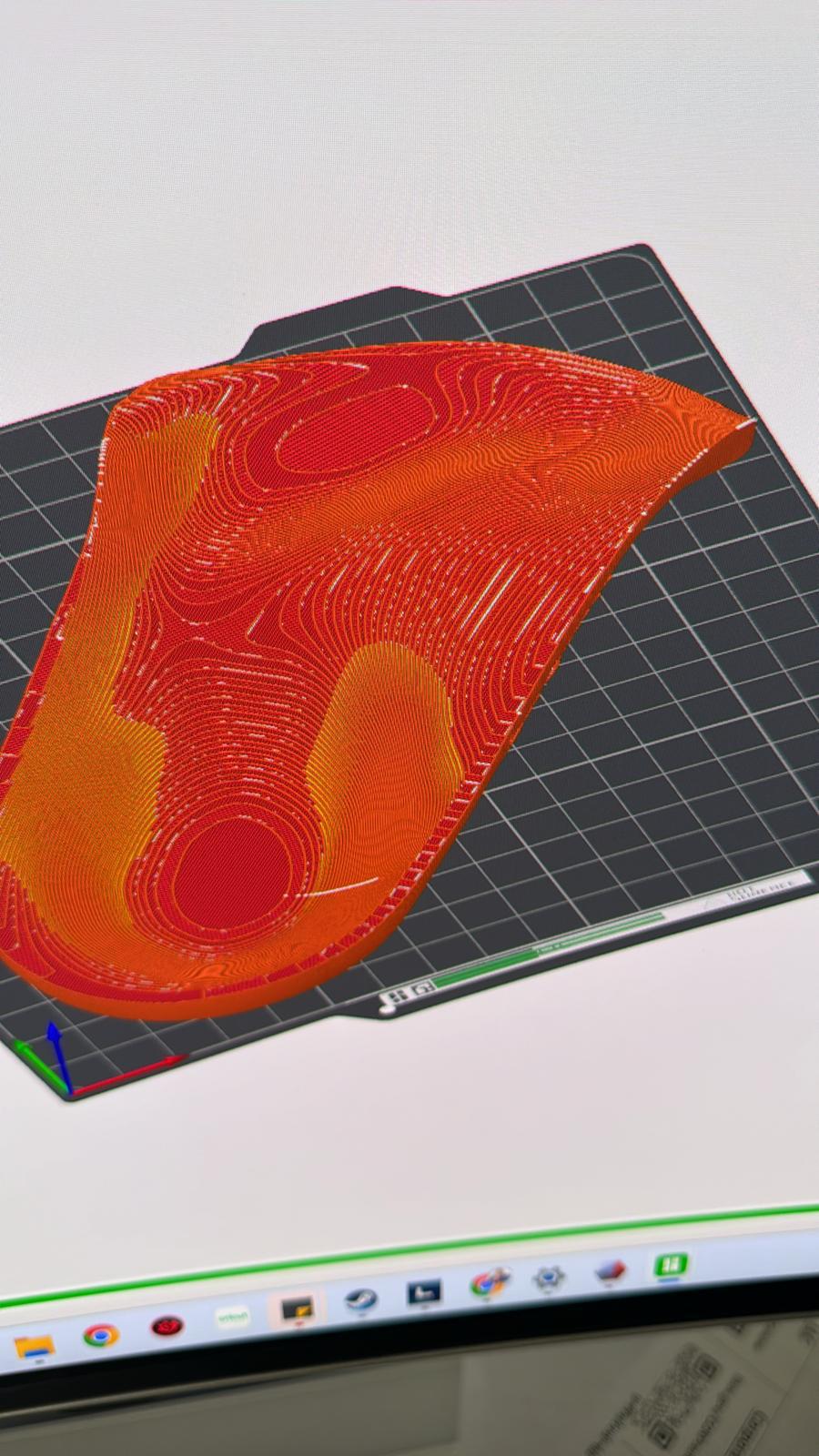

Additive Manufacturing Process

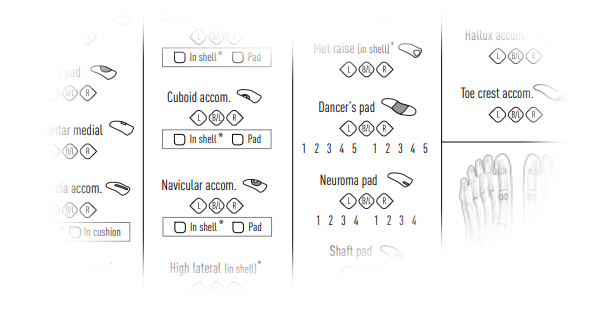

We utilize the latest in high-performance, durable materials for our 3D-printed insoles. These materials are selected for their strength, flexibility, and ability to withstand daily wear and tear. The result is an insole that not only fits perfectly but also lasts longer and performs better than conventional insoles.Our expert designers use sophisticated CAD software to create a digital model of your insole. This process allows for precise adjustments to support specific foot conditions, such as plantar fasciitis, flat feet, or high arches. Each insole is tailored to provide optimal comfort and support, based on your individual needs. Our 3D printers are at the forefront of additive manufacturing technology. They build each insole layer by layer, ensuring precise control over thickness, density, and shape. This process allows us to create complex structures within the insole, such as targeted cushioning zones, that enhance comfort and support.

Advantages Over Traditional Methods

No two feet are the same, and neither are our insoles. The custom nature of our 3D printing technology means that each insole is made specifically for you, addressing your unique foot shape and biomechanics. This personalized approach leads to better foot health, reduced pain, and improved overall comfort.

Our 3D printing process is also eco-friendly. By using additive manufacturing techniques, we reduce material waste and energy consumption, making our insoles not only good for your feet but also better for the planet.

Experience the future of foot care with [Your Company Name]. Our 3D-printed insoles are more than just a product—they’re a personalized solution designed to support your every step.

How It Works: From Scan to Finished Product

It all begins with a precise 3D scan of your feet, capturing every detail to form the foundation of your unique insole design. Our expert designers then use this data to craft a digital model tailored to your specific needs, whether it’s enhanced arch support or targeted cushioning. Using state-of-the-art 3D printing technology, we bring your custom insoles to life with precision and high-performance materials. After a thorough quality check, we ensure the perfect fit before delivering your insoles, ready to provide unparalleled comfort and support with every step you take.

3D Scanned, 3D Manufactured.

Using cutting edge scanning technology to capture tens of thousands of infrared points on the foot, our custom prescription orthotic is accurate and precise to get the correction you need for your patients.

The Future is Here

Modify at your discretion