The OrthoForg3D Process

Detailed Foot/Limb Scanning

We begin by capturing a comprehensive 3D scan of your foot or limb, ensuring every contour and pressure point is accurately mapped for a precise fit.

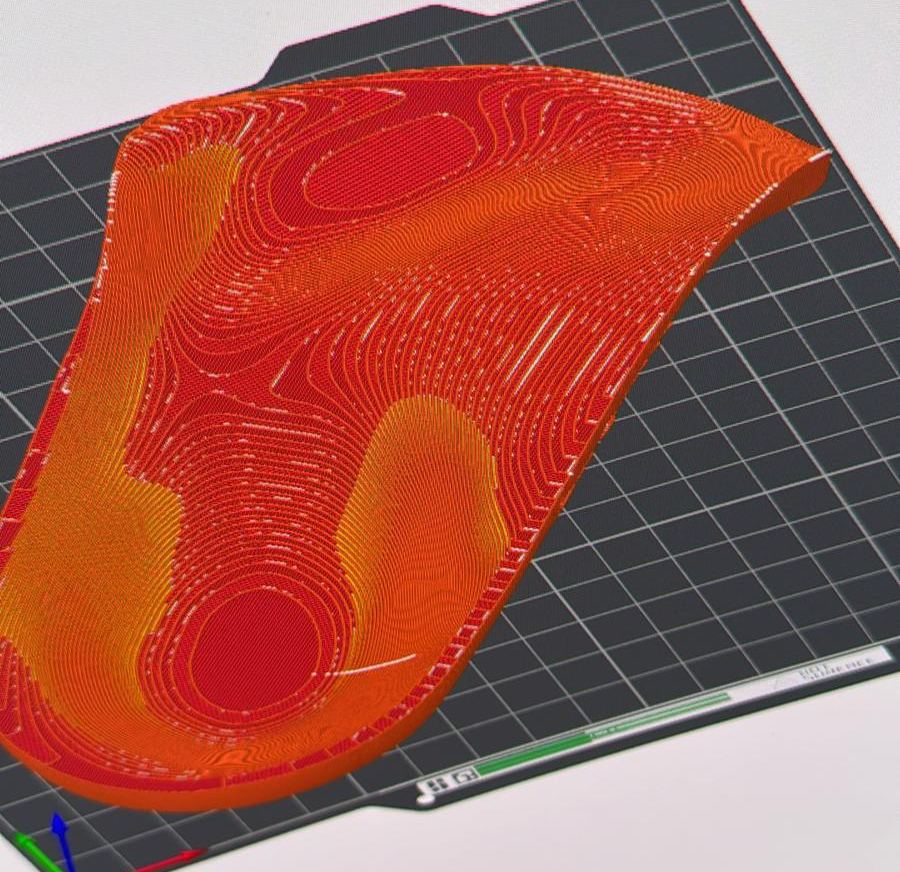

Precision Machining & Manufacturing

Using advanced 3D printing technology, we meticulously manufacture your custom device, layer by layer, from high-performance materials designed for durability and comfort.

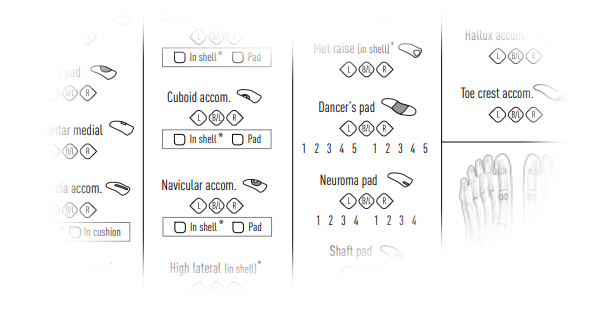

Custom Prescription and Design

Our team of experts analyzes the scan data to create a custom insole or orthotic design tailored to your specific biomechanical needs and comfort requirements.

Post-Fitting Support and Adjustments

We provide ongoing support and make any necessary adjustments to ensure your device continues to meet your needs perfectly over time.

Packaging & Shipping

Your custom device is carefully packaged and promptly shipped to your doorstep, ready for immediate use.

Quality Assurance & Final Fitting

Each device undergoes rigorous quality checks to ensure perfect accuracy and is then fitted to guarantee optimal performance and comfort.

The Future is Here

Modify at your discretion